Product classification

Filling machine

Peristaltic pump

- Basic peristaltic pump

- Flow type peristaltic pump

- Dispensing peristaltic pump

- Industrial peristaltic pump

- Explosion proof peristaltic pump

- Batch type peristaltic pump

- Peristaltic pump OEM

- Peristaltic pump head

- Peristaltic pump tube and accessories

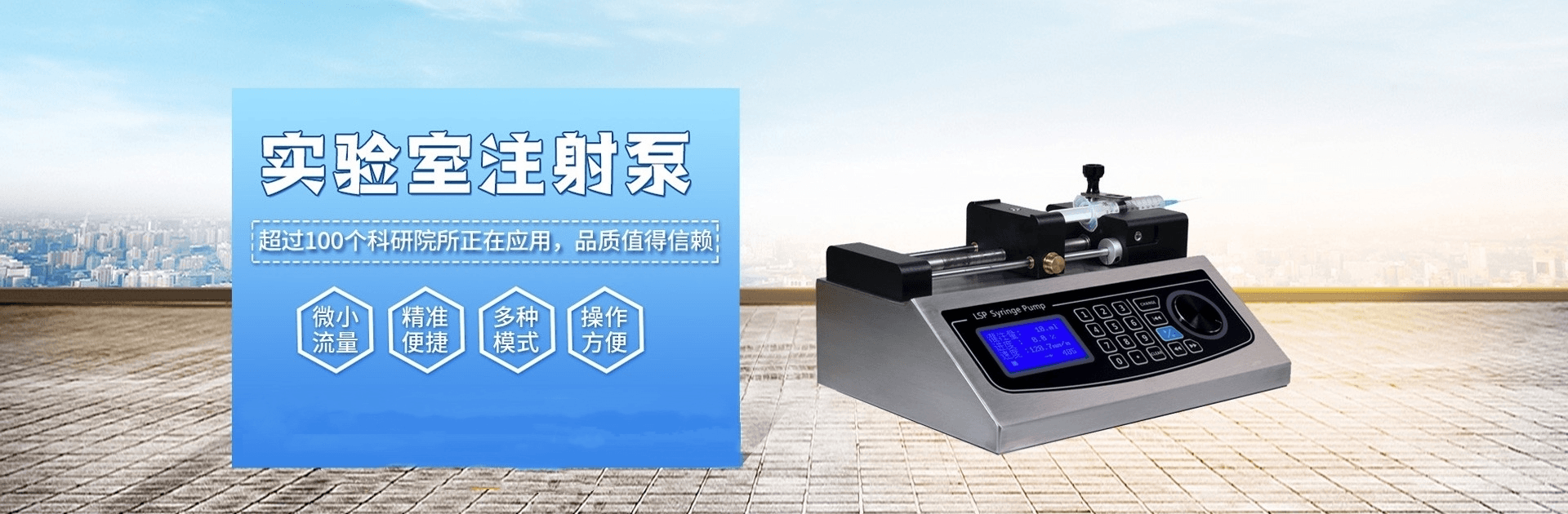

Syringe pump

Precision plunger pump

Contact us

Baoding Ditron Electronic Technology Co., Ltd.

Mobile phone:0086 15231283206

Contacts:sales3@ditrontech.com

Website:www.ditron-tech.com

address:Yunshan road 86,hi-tech zone, Baoding City,Hebei Province,China.

technical knowledge

How to correctly select peristaltic pumps?

First, traffic.

Determine the limit flow (maximum and minimum) of the liquid you need to transport. Choose the corresponding peristaltic pump according to your needs. When determining the flow, you need to consider the following factors:

1. The flow data of all peristaltic pumps are measured with clear water as the medium. The different flow rates of the medium will be different. The high viscosity liquid, the high solid content liquid, the liquid with poor fluidity and so on, the actual flow rate and the marked flow rate will be greatly attenuated.

2. The flow parameters are measured with clear water at micro-lift and suction head. If the suction head is larger, the flow rate will decrease, and the head has less loss to the flow rate.

3. The required flow rate should be within the limit flow rate of the pump, and please consider the influence of the above two factors on the flow rate. In the actual selection, especially in the long-term operation of the pump, we strongly recommend that the pump can meet the flow requirements at low speed (<300 rpm), long-term and high-speed operation, one will reduce the service life of the pump. The other is that the hose will wear out quickly, and your consumables will be very expensive.

Two, determine what you need is an entire pump or OEM product.

1. The so-called whole pump is a standardized product with complete functions and can be operated without professional knowledge.

OEM products are generally processed on behalf of the product, or for bulk parts, users need to have the corresponding professional knowledge, installed on their own equipment to achieve unique functions.

2. The whole pump can be operated by connecting 220V/50Hz civil power or 380V/50Hz power. It can be operated according to the operation instructions without assembly and commissioning. The whole pump can usually be precisely regulated, you have to choose according to the flow, application function, chassis material, protection level and pump head requirements, hose selection.

OEM products you need to consider more factors, price, flow, function, motor, hose, power supply and so on. We provide more power levels, generally divided into AC and DC, AC is divided into single-phase civil and three-phase power, DC is generally divided into 6/12/24V three kinds, DC motor connected to the corresponding DC motor can run (positive and negative poles only determine the direction of the motor will not burn the motor), and stepping motor and No. Brush motor is widely used in peristaltic pump, and it must be connected to the corresponding drive before it can run. Common DC motors can provide a narrow range of speed control board, and stepper motors can provide a wide range of drive control board, but it should be remembered that this circuit board generally needs to be strictly in accordance with the requirements of the positive and negative poles, once the positive and negative poles connected, may burn the circuit board!

Three. Pump head

Pump head is the key component, you have to choose according to the requirements, generally divided into fast-loading type, easy-to-install type and spring type three mainstream pump head, fast-loading type is generally used in OEM products, easy-to-install type is widely used in the whole pump, spring type in OEM and whole pump products have applications, each pump head has its limit flow range, each of which has its own. A pump head is only suitable for clamping a hose with a series of wall thickness.

Four. Choose the pump tube.

Peristaltic pump hose is a professional hose, its size, material, resilience, hardness design are very strict technical requirements!

1, the material selection of the pump tube, especially the liquid to be transported is highly corrosive liquid. According to the nature of the liquid to choose the appropriate material, the current market for domestic hoses or imported hoses, which are made of silicone rubber hoses, resistant to general chemical corrosion, and special requirements of the hose is still dependent on imported products, imported hoses have many materials to choose from, for details see [pump tube resistance] Our product engineers will also make precise recommendations based on the chemical composition you provide.

2. The life factor of the pump pipe, generally the life of domestic silica gel pipe is more than 500 hours (300 rpm, pumping water at room temperature), the import pipe has a long life of flexible pipe, its life can reach 10,000 hours.

3. The quality of domestic silica gel pipe is uneven. The material, processing technology, technical requirements and other factors will directly affect the service life of the hose. Whether users regulate the use, the quality of the pump head and the characteristics of the conveying medium are also key factors.

Determine the limit flow (maximum and minimum) of the liquid you need to transport. Choose the corresponding peristaltic pump according to your needs. When determining the flow, you need to consider the following factors:

1. The flow data of all peristaltic pumps are measured with clear water as the medium. The different flow rates of the medium will be different. The high viscosity liquid, the high solid content liquid, the liquid with poor fluidity and so on, the actual flow rate and the marked flow rate will be greatly attenuated.

2. The flow parameters are measured with clear water at micro-lift and suction head. If the suction head is larger, the flow rate will decrease, and the head has less loss to the flow rate.

3. The required flow rate should be within the limit flow rate of the pump, and please consider the influence of the above two factors on the flow rate. In the actual selection, especially in the long-term operation of the pump, we strongly recommend that the pump can meet the flow requirements at low speed (<300 rpm), long-term and high-speed operation, one will reduce the service life of the pump. The other is that the hose will wear out quickly, and your consumables will be very expensive.

Two, determine what you need is an entire pump or OEM product.

1. The so-called whole pump is a standardized product with complete functions and can be operated without professional knowledge.

OEM products are generally processed on behalf of the product, or for bulk parts, users need to have the corresponding professional knowledge, installed on their own equipment to achieve unique functions.

2. The whole pump can be operated by connecting 220V/50Hz civil power or 380V/50Hz power. It can be operated according to the operation instructions without assembly and commissioning. The whole pump can usually be precisely regulated, you have to choose according to the flow, application function, chassis material, protection level and pump head requirements, hose selection.

OEM products you need to consider more factors, price, flow, function, motor, hose, power supply and so on. We provide more power levels, generally divided into AC and DC, AC is divided into single-phase civil and three-phase power, DC is generally divided into 6/12/24V three kinds, DC motor connected to the corresponding DC motor can run (positive and negative poles only determine the direction of the motor will not burn the motor), and stepping motor and No. Brush motor is widely used in peristaltic pump, and it must be connected to the corresponding drive before it can run. Common DC motors can provide a narrow range of speed control board, and stepper motors can provide a wide range of drive control board, but it should be remembered that this circuit board generally needs to be strictly in accordance with the requirements of the positive and negative poles, once the positive and negative poles connected, may burn the circuit board!

Three. Pump head

Pump head is the key component, you have to choose according to the requirements, generally divided into fast-loading type, easy-to-install type and spring type three mainstream pump head, fast-loading type is generally used in OEM products, easy-to-install type is widely used in the whole pump, spring type in OEM and whole pump products have applications, each pump head has its limit flow range, each of which has its own. A pump head is only suitable for clamping a hose with a series of wall thickness.

Four. Choose the pump tube.

Peristaltic pump hose is a professional hose, its size, material, resilience, hardness design are very strict technical requirements!

1, the material selection of the pump tube, especially the liquid to be transported is highly corrosive liquid. According to the nature of the liquid to choose the appropriate material, the current market for domestic hoses or imported hoses, which are made of silicone rubber hoses, resistant to general chemical corrosion, and special requirements of the hose is still dependent on imported products, imported hoses have many materials to choose from, for details see [pump tube resistance] Our product engineers will also make precise recommendations based on the chemical composition you provide.

2. The life factor of the pump pipe, generally the life of domestic silica gel pipe is more than 500 hours (300 rpm, pumping water at room temperature), the import pipe has a long life of flexible pipe, its life can reach 10,000 hours.

3. The quality of domestic silica gel pipe is uneven. The material, processing technology, technical requirements and other factors will directly affect the service life of the hose. Whether users regulate the use, the quality of the pump head and the characteristics of the conveying medium are also key factors.