Product classification

Filling machine

Peristaltic pump

- Basic peristaltic pump

- Flow type peristaltic pump

- Dispensing peristaltic pump

- Industrial peristaltic pump

- Explosion proof peristaltic pump

- Batch type peristaltic pump

- Peristaltic pump OEM

- Peristaltic pump head

- Peristaltic pump tube and accessories

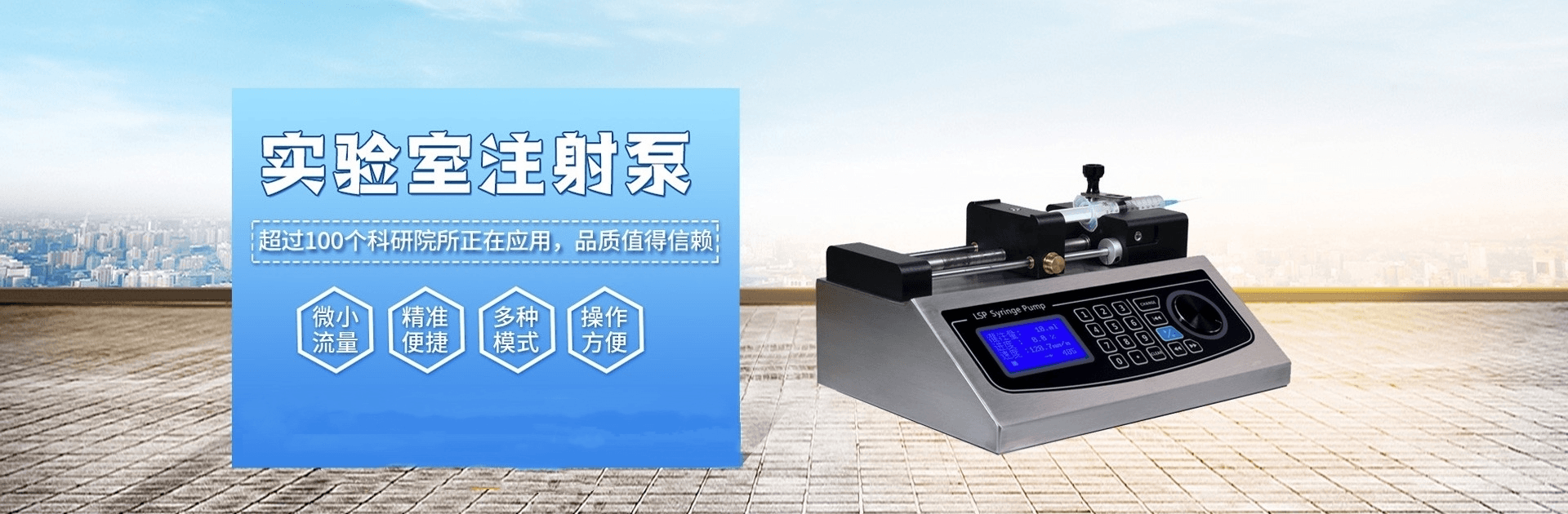

Syringe pump

Precision plunger pump

Contact us

Baoding Ditron Electronic Technology Co., Ltd.

Mobile phone:0086 15231283206

Contacts:sales3@ditrontech.com

Website:www.ditron-tech.com

address:Yunshan road 86,hi-tech zone, Baoding City,Hebei Province,China.

technical knowledge

How do we do when the edible oil filling machine is still closed after it is closed?

With the rise of edible oil filling machine in the industry, the rapid production speed and stable performance become synonyms of edible oil production. However, the sharp rise in market demand has also led to the emergence of the production line. The appearance of filling line greatly improves the production efficiency, and the improvement of automation degree is favored by enterprises. However, with the edible oil filling machine production line, many enterprises will encounter such a problem, in peacetime how to maintain the filling line? How to solve the problem? Filling line will drop oil after closing, which is a very common problem, let's see how to solve it.

First of all, check whether the orifice of the filling nozzle of the filling head is damaged, and take out the filling nozzle to trim the orifice. The diameter of the orifice can not be greater than 7.5mm. After repairing the aperture, grind the hole on the water abrasive paper.

Another possibility is that the ball valve in the filling head is damaged and the oil leakage fault can be solved by replacing the ball valve.

The emergence of filling production lines for the production of edible oil to improve production efficiency, and want to give full play to the advantages of the edible oil production line, daily maintenance is a must to do. Do you want to make the equipment edible oil life longer, and the failure rate is getting smaller and smaller? Let's start with routine maintenance.

First of all, check whether the orifice of the filling nozzle of the filling head is damaged, and take out the filling nozzle to trim the orifice. The diameter of the orifice can not be greater than 7.5mm. After repairing the aperture, grind the hole on the water abrasive paper.

Another possibility is that the ball valve in the filling head is damaged and the oil leakage fault can be solved by replacing the ball valve.

The emergence of filling production lines for the production of edible oil to improve production efficiency, and want to give full play to the advantages of the edible oil production line, daily maintenance is a must to do. Do you want to make the equipment edible oil life longer, and the failure rate is getting smaller and smaller? Let's start with routine maintenance.